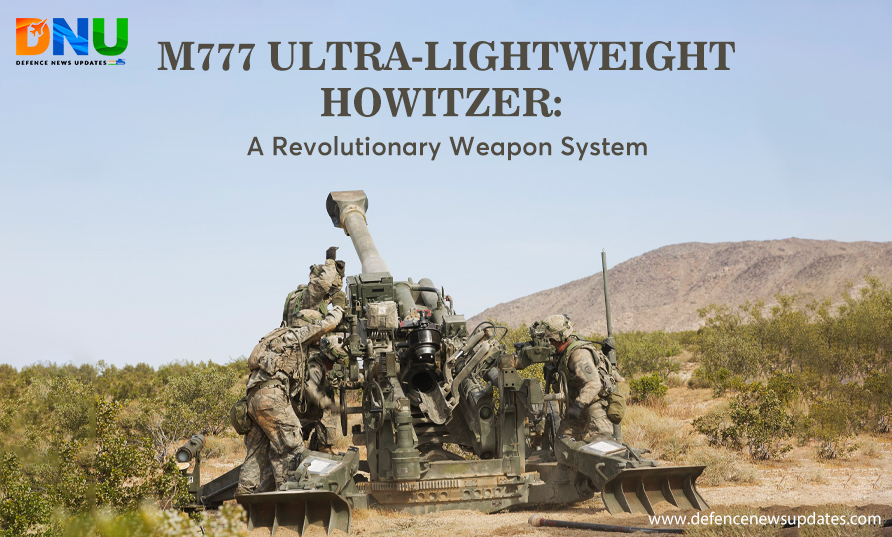

- Initially developed for the U.S. Marine Corps and the U.S. Army as their next generation Medium Force weapon, the M777 has become the benchmark for 155mm Lightweight Towed Artillery Systems.

- The first 18 systems were delivered to the US Army’s 2nd Battalion, 11th Field Artillery in Hawaii in October 2006.

The BAe (British Aerospace) M777 howitzer is the main piece of towed artillery in the US military. It has largely replaced the M198 howitzer, which it replaced. It is one of the smallest and lightest weapons of its kind ever made. This is because it is made of a titanium alloy and as much weight as possible has been taken out of it. Even though it is made in the United States, the M777 is based on a British design.

The M777 started out as a private project by Vickers (which later merged with BAe, the current manufacturer) in the early 1980s. They wanted to make a 155 mm howitzer that was very light and could be sold on the export market. The US Army was the main customer for this new weapon.

They had just started using the M198 howitzer, but they didn’t like it. The M198 was designed to be mobile and easy to move by air, but it was still pretty heavy at over 7,000 kg. Vickers was sure that if they simplified the design of a 155 mm howitzer and used a lot of light materials to build it, they could make a weapon with the same firepower as the M198 that weighed just over half as much.

Since most weapons of this type are much heavier, figuring out how to make a 4-ton 155mm/L39 towed howitzer took some time and effort. The first draught of the design wasn’t ready until the spring of 1987. The main problem was figuring out how to use titanium alloys instead of traditional steel to make the new weapon.

Titanium is very strong, but it is also very expensive and has a very high level of hardness, which makes it notoriously hard to machine. Soon after, the design was shown to the US Army, which was interested in the idea of using such a weapon. In September 1987, the Army gave permission to build two prototypes. Since it is against the law for the US military to buy weapons made in other countries, Vickers and Textron worked together to make this weapon in the US. Royal Ordnance also came up with a design, and its development was similar to that of the Vickers design.

Two prototypes of the Vickers design, which is now called the LW155 (short for 155 mm Lightweight Howitzer), were made and sent to the Army at the end of 1989 for testing and evaluation. During this time, the US Marine Corps was also interested in the LW155. They saw a use for it in their operations, where the weight of an artillery system was limited. In 1990, the USMC also looked at the LW155.

In the late 1990s, there was a formal competition between the LW155 and the Royal Ordnance design, which at the time was called the “Light Towed Howitzer.” The LW155 won the competition. After making this choice, the US Army gave the LW155 the official name XM777.

But even though the media made a big deal out of the fact that the XM777 passed its development tests, it had trouble right away during its operational testing. Under conditions that were more like how the gun would be used in the field, serious problems with metal fatigue, instability while firing, and damage caused by recoil became clear quickly. By 1998, these problems were clear, and the XM777 (and later the M777) kept having them for many years. Some have never been fully-resolved.

Textron left the XM777 programme in 1999. This meant that BAe had to make the weapon without a US subcontractor for more than a year. By September 2000, BAe was able to get smaller companies to make the weapon instead. Each of these smaller companies was to make a different part of the M777.

Video by Lance Cpl. Brandon Salas

The carriage was going to be made by HydroMill Inc., the stabilisers, spades, and stabilisers were going to be made by Major Tool and Machining Inc., the loading tray was going to be made by Rock Island Arsenal, the elevation mechanisms were going to be made by Wegmann, the optical fire control system was going to be made by Seiler Instruments and Mfg., the traverse track was going to be made by Rotek Inc., and the titanium alloys needed to make the whole The titanium castings for the XM777 were made by three different companies.

In 2002, the DoD gave BAe a $135 million contract to start the Low Rate Initial Production (LRIP) phase of the XM777 and type-classified it as the “M777.” This was despite the fact that there were many ongoing problems and technical issues with the design.

Under the LRIP contract, 94 howitzers were to be built, and the first one was done in February 2003. Even though it was against the law, BAe’s factory in the UK ended up making 30% of the M777. This included the suspension, running gear, and upper cradle.

When compared to most other towed howitzers, the M777 looks very different, which makes it easy to spot. The rectangular muzzle brake is very hollow and has two huge baffles that stand out. The spike-shaped towing eye is attached to the bottom of the muzzle brake. The M777 is unusual in that it has no trails. The M777 looks very different when it is in its travelling position and when it is in its firing position.

The M777 sits very low to the ground when it is in place, with its stabilisers swung forward and its spades dropped to the ground behind it. It is so low that when the tube is in a level position, it is only about half a metre off the ground.

Even though the M777 has a low profile, it is easy to raise the gun on it because the pivot point of the gun cradle is behind both the saddle and the carriage body. You can also slightly press down on the tube, but this isn’t done very often. From above, a fully-placed M777’s spades and stabilisers look like a cross, which is important for keeping it stable since it doesn’t have traditional trails.

Even stranger is how the M777 looks when it is set up for travel. Unlike most modern howitzers that are towed, the M777’s gun doesn’t have to be turned 180 degrees to be pulled. Instead, the whole gun is pulled by the spike-like towing eye on the muzzle brake, which we already talked about. In its travel position, the two back spades are folded up and a little bit forward, but they don’t wrap around the saddle.

Most of the M777 is made of titanium alloy, but some structural parts are made of aluminium and the gun tube is made of steel. Many parts of the M777 have more than one job, instead of having a separate part for each job.

This is an interesting way to save weight. For example, the suspension’s hydraulics can also be used as a hydraulic jack. Behind the breech on the right side is a loading tray that is operated by hydraulics, but there is no rammer. The standard M777 has an optical sight on the left side and space on the right side for a second sight if needed.

For the M777 to work normally, it needs a crew of eight people. It can also be used by as few as five men in a pinch, but it will fire at a much slower rate. Some publications have said that the M777 is the first 155 mm howitzer that can be fired by only five people, but the M198 could also be used in the same way.

The M777 takes three minutes to land, and it takes between two and three minutes to take off. The M777 can fire 4 rounds per minute for up to 2 minutes, but it can only fire 2 rounds per minute all the time.

Most of the time, the digital fire control system is used to aim the M777A1 and A2’s indirect fire. It has fast and accurate ballistic computation, navigation, pointing, and self-location. This lets the M777A1/A2 carry out effective fire missions quickly, cutting down on the time it needs to be set up in a certain place. The first M777 didn’t have this fire control system, so the crew had to use calculators and dials to figure out how to fire. All M777s can fire straight ahead and are aimed with day and night optical sights.

The M777 can use a lot of different kinds of ammunition. Here are a few examples.

The M107 HE round used to be the main projectile for the M777, but this round is slowly being used up in service and is being replaced by the M795 HE round. This 46.7 kg projectile has a 10.8 kg explosive charge, which could be TNT or IMX-101, depending on the customer (the US Army uses a TNT filler, while the USMC uses IMX).

The M795 has a range of up to 22.5 km and a CEP of 50 m when fired from an M777 with an M119 or M203 propellant charge. The USMC says that the M109 round is 30% more deadly than the M107 round because it has a better charge-to-weight ratio and a much better shrapnel and splintering pattern.

However, projectiles with high charge-to-weight ratios tend to have less penetration (an important consideration when engaging armour and hardened structures). Even though stocks are slowly running out, the M107 is still used with the M777.

One of the most used projectiles for the M777 is the M982 Excalibur. This is a GPS-guided HE round with fin stabilisation and near-pinpoint accuracy (the CEP is said to be only 5 m). When fired from a 155 mm/L39 weapon, it has a range of up to 40 km and can be safely fired much closer to friendly troops than an unguided projectile can. The Excalibur’s programmable guidance system lets the crew set it to land in a specific place.

This lets front-line troops calling in fire missions choose specific high-priority targets for single projectiles to destroy (for example, a particularly problematic enemy pillbox). The Excalibur has GPS guidance, but it also has inertial guidance. This helps the projectile keep its ballistic arc even when GPS is heavily jammed, and it also gives it some guidance when GPS isn’t working at all (though it won’t be as accurate). The Excalibur weighs 48 kg and has a PBXN-9 warhead that weighs 22 kg.

The unit cost of the Excalibur is said to be anywhere from $10,000 to $214,000 by different sources, but these numbers are wrong. A close look at the DoD’s Selected Acquisition Reports shows that a total of $14,691 billion was spent on developing and making the planned 7,474 Excaliburs. This means that each Excalibur actually cost $22,284 million, which is more than a thousand times more than what the DoD says. Because of this, the Excalibur costs more than the M777 itself.

The M549A1 RAP-HE is a rocket-boosted HE round that, when fired from the M777 with the Zone 8S M203 Propellant Charge, has a range of 30 km. Before the fuze is set, the M549A1 weighs 43.6 kg and has a 6.8 kg bursting charge.

The M864 DPICM (Dual-Purpose Improved Conventional Munition) is a submunition-dispersing projectile that, as it falls, breaks open and scatters a large number of anti-personnel and anti-material grenades over a wide area. It is also known as a “cluster munition.” The payload is made up of 24 M46 and 48 M42 grenades. Both have a shaped charge (called “High Explosive Anti-Tank,” or “HEAT”) and a secondary fragmentation effect, which makes the M864 useful against a wide range of targets. The M864 has a range of 30 km and weighs 47 kg. This is because it has a “base burner” rocket booster.

The M777 can also shoot smoke and a wide range of projectiles that can break up mines. The M777 can also fire the laser-guided artillery projectile M712 Copperhead, but since only 20,000 were made and production stopped decades ago, the stockpile is quickly running out. The M777 can also fire any 155 mm shells that meet NATO standards. This gives it a much wider range of ammunition to use. So, when training and fighting with the M777, its operators may sometimes need to use more unusual foreign ammunition.

Canada was the first country to use the M777 in combat during the Afghan War. They did this in early 2006 as part of Operation Archer. The M777 was said to be very effective in this campaign, killing a lot of Taliban. According to reports, only two guns did most of the damage to the Taliban. The Canadian M777s were still used all through 2006. The need for fire support from these weapons seems to have been pretty big, but so did the amount of ammunition used because of it. At the beginning of 2007, it was said that the Canadian Army was running out of 155 mm ammunition in that theatre. This meant that the Canadian Army had to fire fewer rounds during each fire mission and fewer fire missions overall.

The US first sent the M777 into combat in Iraq and Afghanistan at the end of 2007, and the first US M777 fire missions happened in January 2008. Even though many of the Army’s M777s have been taken out of Iraq for a long time, the US Marines sent their first M777 batteries there in March 2016. As of the middle of 2016, M777s are still firing in anger to support operations in Iraq and Afghanistan, even though many in the media have said that the US’s role in those conflicts is pretty much over.

Even though the M777 is much lighter than almost all other 155 mm howitzers, it doesn’t have the APUs that many other modern towed howitzers, like the FH-70 and G-5, have that can be used to move the howitzer. The M777 has no power for moving up and down or side to side. So, someone has to move the M777 into place. There is also no rammer, so several crew members must use their own strength to force each shell and powder charge into the breech using a long, curved ramrod.

The 4-ton weight of the M777 was supposed to make it easy to move by vehicles that couldn’t move the M198. However, in the field, only heavy-lift helicopters and 6×6 cargo trucks are used to move it. Even though it can be moved by HMMWVs and helicopters as small as the UH-60, this is rarely done. This is probably because of safety rules and the fact that the M777 has been getting heavier since its first field tests. Most of the time, a CH-47 Chinook, a CH-53E Super Stallion, or a V-22 Osprey, which are all very different from the UH-60 Blackhawk, is used to fly the M777s.

Reducing the weight of the weapon has no effect on the weight or size of its ammunition or the field supply trains that are needed to carry it. These are much more important issues than how to move the weapon itself.

There are many problems with using titanium instead of steel. These problems stem from the fact that titanium alloys are much harder and less flexible than steel alloys. This makes them more prone to metal fatigue (making them immensely expensive to machine). The M777’s odd shapes are also a result of the ruthless effort to cut down on weight, and these pose their own serious problems in everyday use. Also, this piece of artillery is too light for the strong 155 mm rounds.

The force of a gun’s recoil is stronger the lighter it is for a given projectile and propellant charge. Because of this, the mechanisms in the M777 that absorb recoil wear out dangerously fast in combat. There isn’t much hope that these problems with the M777 can be fixed completely.

The length of the M777’s tubes is also an important problem. In the 1960s, the US Army started using 155 mm/L39 howitzers. By the early 1980s, 155 mm/L45 howitzers had surpassed the 155 mm/L39 in terms of development, production, and spread around the world. These, in turn, are being replaced by 155 mm/L52 howitzers all over the world.

The South African Border War, the Rhodesian Bush War, the Yom Kippur War, and the Vietnam War all showed how dangerous it is to have artillery with a much shorter range than the enemy. In all of these wars, the side with shorter-range guns lost because their artillery was constantly destroyed by longer-range enemy fire, while the side with shorter-range guns was free to fire without fear of being hit.

Even though the Excalibur projectile has a long range of 39 km, it doesn’t solve this problem. Equivalent ammunition fired from 155 mm/L45 and 155 mm/L52 weapons (like the G-5-52 howitzer) still has a significant range advantage, leaving the US military open to the same kind of destruction their fire bases faced when they were hit by the Soviet M-46 130 mm field gun during the Vietnam War.

By 2022, the United States, Australia, Canada, India, Saudi Arabia, and Ukraine were all using the M777. India has asked for 145 M777A2s in 2016. (though India has proven a dangerous market for artillery producers; this sale follows in the wake of the Denel and Bofors scandals, both resulting in the cancellation of major arms deals due to alleged improprieties). India had received a total of 89 M777 howitzers by 2022, and another 56 were set to arrive by June. Only 25 howitzers were sent to India by BAE Systems at first. Mahindra Defence put together the rest of them in India. These are being put to use in mountainous areas near the China border.

| Country of origin | UK and US |

| Entered service | 2005 |

| Crew | 8 men |

| Armament | |

| Gun bore | 15mm |

| Barrel length | 39 calibers |

| Projectile weight (M795 HE) | 46.7 kg |

| Maximum range of fire (M795 HE) | 22.5 |

| Maximum range of fire (RAP-HE) | 30 km |

| Maximum range of fire (M982Excalibur) | 39 km |

| Maximum rate of fire | 4rpm |

| Sustained rate of fire | 2 rpm |

| Elevation range | -2.5 to +72 degrees |

| Traverse range | 46 degrees |

| Dimensions and weight | |

| Weight | 4.2 t |

| Length (in travelling order) | 9.51 m |

| Length (in combat order) | 10.21 m |

| Mobility | |

| Towing vehicle | 6×6 truck |

| Road towing speed | 74 km/h |

| Cross-country towing speed | 24 km/h |

| Emplacement | 3 minutes |

| Displacement | 2-3 minutes |

In 2022, the US, Australia, and Canada gave 142 M777 howitzers to Ukraine so they could defend themselves against a Russian invasion. Most of the howitzers, at least 90, came from the stocks of the US Marines. At least 6 units were given by the Australian army, and at least 4 units were given by the Canadian army. These howitzers worked well against the Russians and made a big difference on the battlefield.

Columbia is the only other country that has said it will buy M777s. The US Marine Corps is planning to give some howitzers to the Columbian naval infantry. The UAE has said it wants to buy the M777’s weapons, which it would use to make its own self-propelled version. In 2016, BAE Systems said that it is working with Emirates Defense Technology to make a version that can move on its own.

The M777 has sold a lot, and production is still going on. About 1,200 pieces have already been finished. As of the recent deal to sell 145 M777s to India for $750 million, each one costs $5.17 million. Even though the M777 has had a lot of publicity and has been on the market for over 20 years, it has a very small number of customers. This is mostly because it costs a lot. A typical 155 mm howitzer costs about one-tenth as much.

Variants

LW155: The M777 prototype was built in the late 1990s. It has also been called the “155LW” by some sources.

XM777: More versions of the M777 prototypes, which had more improvements and fixes as the M777 was still being made.

M776: The M777’s weapons, but without the rest of the system. The M776 uses a modified version of the M284 tube that is used in the M109A6 Paladin.

M777: Basic model for mass production that isn’t too different from the LW155. The basic M777 was just the low-cost first model made, and all of them, except for a few that are on display, are being changed back to ‘A1 or ‘A2 standard.

M777A1: Instead of an optical sight, the gun is equipped with a digital fire control system. The original M777 was quickly passed by this version in terms of development. It was called “M777E1” while it was being made. In 2004, test firings were done. In 2005, a contract was given to make 495 M777A1 howitzers for the US Army and US Marine Corps.

It made the M777A1 the only production model that mattered during that time. From 2006 to 2009, the “A1” models were to be made. Some were once M777s that were changed. During this time, the Canadian Forces also put in an order for several M777s.

M777A2: The M777A1 is the same, but it comes with software that lets you use Excalibur GPS-guided shells. The M982 Excalibur was tested for the first time from the M777 in 2003, but the operational tests from the M777A2 weren’t finished until 2007. At that time, Excaliburs were already in use in Afghanistan.

M777ER: This weapon is an experimental version of the M777A2 with a 52-caliber tube. Its name stands for “M777 Extended Range.” Even though the new barrel greatly extends the range, the M777ER is 1.8 m longer and 450 kg heavier than the M777A2. This could make it harder to move, keep balanced, and control. Status of the programme is unknown.

M777 Tilt Bed Carrier: Early model of a carrier for an M777 howitzer that would carry the gun while moving and then drop it on the ground when it was time to use it. Didn’t make it into production.

M777 Portee: British howitzer. It is a mix of howitzers that are towed and those that are mounted on trucks. It is armed with the M777’s weapons. Did not go into production because there wasn’t enough money.

Brutus: Based on an M1083 6×6 military truck chassis, the M777’s guns were used to make an experimental US truck-mounted howitzer.

Similar Weapons

Royal Ordnance also made a competing design for the Light Towed Howitzer. This weapon was made in a much more standard way and had very long standard trails that were also used to pull it. Did not get made or put into service.

2A61 Pat-B: The 2A61 is a Russian lightweight towed howitzer that was made in the 1990s. It has a bore of 152 mm and weighs only 4,300 kg, making it one of the few pieces of artillery in the world with the same bore and weight as the M777. It is also pulled by its muzzle, like the M777, and instead of trails, it has stabilisers. Even though the evaluation took a long time and there was no official rejection, no orders for production were placed. The 155 mm version for export is the M-389. Like its predecessor, the M-389 never sold anything.

The AH-4 is a copy of the M777 made in China. It has a 155 mm/L39 tube. It weighs 4,500 kg all together. Depending on the type of bullet, the maximum range is between 25 and 40 km. This gun system was made public in 2014.

SLWH Pegasus: The Pegasus was made by ST Kinetics in Singapore. Like the M777, it has a 155 mm/L39 tube, is made of titanium and aluminium, and weighs 5,300 kg.

Design and construction of the Ultralightweight Field Howitzer

The M777 is mostly made of titanium and titanium castings. This makes it 3,175kg (7,000lb) lighter than the M198 howitzer, which it replaces in the US Army and USMC’s arsenal. RTI International Metals in Niles, Ohio, supplies the titanium.

M777 armament

The M777 has the same amount of firepower as 155mm towed systems of the same generation, but it weighs less than half as much. The howitzer has a barrel that is 39 calibres. At Charge 8 super, the gun’s muzzle speed is 827m/s.

With unassisted rounds, the maximum firing range is 24.7 km. With rocket-assisted rounds, the maximum firing range is 30 km. Using the Modular Artillery Charge Systems, the M777A2 can fire the Raytheon/Bofors XM982 Excalibur GPS/Inertial Navigation guided long-range 155mm projectiles (MACS). Excalibur can shoot up to 40 km away and is accurate to within 10 m.

In August 2003, the M777A1 was used to test fire Excalibur for the first time. In September 2006, the first production rounds were sent out. In March 2007, Excalibur passed a limited user test with flying colours. It was first used in Iraq in May 2007 and in Afghanistan in February 2008.

Under intense firing conditions, the M777 can fire up to five rounds per minute, and it can keep firing at a steady rate of two rounds per minute.

Fire control

The LRIP systems have an optical sighting system that lets them fire both directly and indirectly, day or night. The General Dynamics Armament Systems Towed Artillery Digitisation (TAD) system is built into all systems that go into full production. TAD will be added to LRIP systems after the fact.

The TAD digital fire control system includes a laser ignition system, electric drives for the howitzer’s traverse and elevation, and a powered projectile rammer. It also does on-board ballistic computation, navigation, pointing, and self-location, which gives it more accuracy and faster response times.

M777 mobility

The M777 weighs 3,745 kg when it is finished, and it can be moved by helicopter, transporter plane, or ship. A 4×4 with air brakes that weighs more than 2.5t can pull the howitzer.

The hydrostrut suspension system was made by a company in the UK called Horstman Defence Systems. The maximum speed on the road is 88 km/h, and the maximum speed off-road is 50 km/h.

The towing eye can hold up to 60 kg, and it has a ground clearance of up to 660 mm.

Facebook Comments