One of India’s enduring demanding situations in army and civil aviation has been the lack of ability of Indian enterprise and studies companies to layout and convey an indigenous jet engine. Indian civil aviation enterprise absolutely imports its aircraft, and the dearth of an indigenous engine stymies any strive with the aid of using establishments like NAL and HAL from being capable of convey out even a small jet-powered civilian plane.

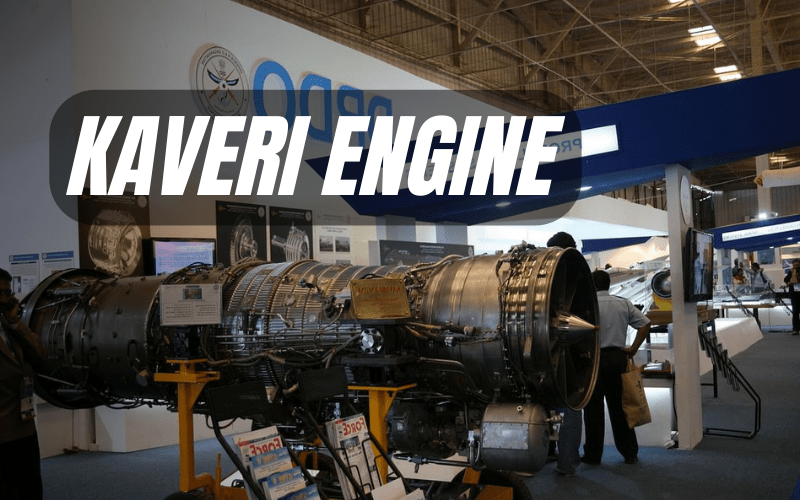

In army aviation, the identical saga continues, with the much-hyped after which much-maligned indigenous Kaveri jet engine being separated from the TEJAS fighter jet software after which left to die a gradual death. Our indigenous software to construct fighter jets is having to make to do with overseas engines, which themselves are best doled out to us instead miserly with the aid of using the US.

The truth stays that the GE-F404 Engine utilized by TEJAS is inadequate to electricity the aircraft, decreasing its payload and variety. Similarly, the GE-F414 engine deliberate for TEJAS MK-II is further underpowered to satisfy all of the necessities of IAF withinside the medium-weight fighter magnificence of 15–18-ton variety to allow a 5-ton fight payload and a fight variety of six hundred km on inner fuel.

Even the AMCA/TEDBF deliberate/fantasized about, are all slated to be powered with the aid of using GE-F414, which might restriction the dimensions and payload in addition to variety of the fighter jets with the aid of using layout. So, why is India compelled to compromise its high-priced and extraordinarily critical fighter jet software with underpowered engines? Why can not India efficaciously construct its personal engines?

The solution to the above query lies withinside the truth that jet engine era has been extra carefully guarded with the aid of using international locations and their organizations than even nuclear reactor know-how. Jet engines are famously complicated machinery, containing as a minimum 30,000 transferring and static parts, requiring excessive-cease metallurgy studies in addition to a completely excessive diploma of precision and talent in forging, casting and machining.

Once designed and positioned together, jet engines require widespread checking out in wind tunnels and sooner or later on flying testbeds, having to clock loads and hundreds of hours to apprehend the fatigue traits in addition to degradation of every man or woman part, amongst 100 different studies.